| Payment & Shipping Terms | Supply Capacity |

|---|

| Unit Price: | 2.0 USD | Production Capacity: | 50000 pcs/month |

| Trade Term: | FOB,CFR,CIF,EXW | Packing: | cartron box |

| Payment Terms: | T/T, WU, Money Gram | Delivery Date: | 20 days |

| Min. Order: | 5 Piece/Pieces | | |

| Means of Transport: | Ocean, Air, Land | | |

We offer quality sealing and cost-effective oil seal designs that help

keep equipment running longer while reducing downtime. Through our

comprehensive selection we provide oil seals with short lead times and

with a variety of designs for use in many common and more challenging

industry applications. When selecting an oil seal, it is important to

know what sort of design is needed, and we have outlined a few of the

more common

elements below.

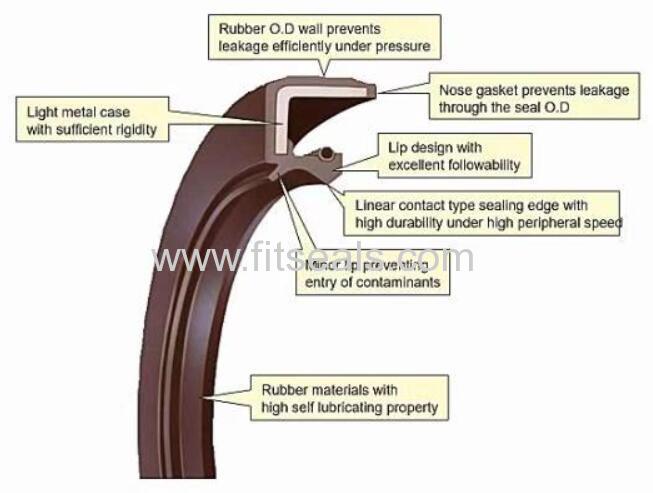

Standard Sealing LIP Designs

oilseals-102-2Our

oil seals have many different available lip designs, with some being

simple and others complex, due to their special application. However,

the most common industry lip standards are described below:

(single

lip): This design uses a garter spring and generally seals against

internal media in lower pressure applications. The single lip is not

recommended for use in applications in which the environment contains

dirt or contaminants.

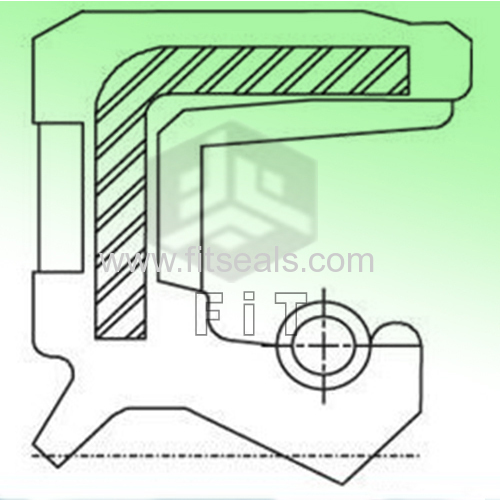

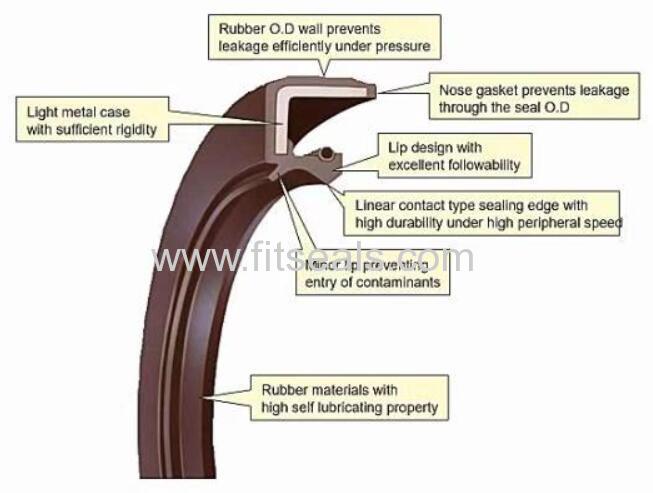

(double lip): This design is also used with a

garter spring and consists of a primary lip for sealing against internal

media in lower pressure applications. The secondary (also known as the

auxiliary lip) provides additional protection from dust and dirt.

(dual

or twin lip): This design consists of garter springs and two identical

primary lips that are usually used to separate two liquids. The space

in between these two excellent lips must be lubricated with grease or

something similar.

(single lip): This design has NO spring and is

generally used for sealing a non-pressure medium, such as grease or

protecting against dirt.

(double lip): This design has NO spring and

is generally used for sealing a non-pressure medium, such as grease and

is used to protect against dirt as well as internal and external media.

Metal Case Finishes & Treatments

Oil seals with

outer metal cases may include finishes or treatments that are appliedto

the outer edge to aid in rust protection, identification, and sealing of

scratches Or imperfections in the housing bore. Common finishes applied

to the outside edge of metal O.D. oil seals include: Plain (a bonding

agent that is usually a yellowish-green color), a Color Painted edge,

and a grinded-polished edge.

Oil Seal Style Selection (Common Types)

Combining both the lip and case types explained above, it is easy to assemble the Global

O-Ring and Seal (GOR) types as indicated in the following examples:

Type SC: Single lip w/spring, rubber covered O.D.

Type TC: Double lip w/spring, rubber covered O.D.

Type SB: Single lip with spring, metal O.D.

Type TB: Double lip with spring, metal O.D.

Type SA: Single lip w/spring, reinforced metal O.D.

Type TA: Double lip w/spring, reinforced metal O.D.

Factors in Oil Seal Selection

Our oil seals are available in both inch and metric sizes and are selected as follows:

Type: Combination of lip design and case type.

Shaft

Diameter: The outside diameter of the shaft where the seal will operate

(sometimes referred to as the I.D. of the oil seal)

Bore Diameter:

The inside diameter of the bore housing where the seal will operate

(sometimes referred to as the O.D. of the oil seal)

Width (or Depth): The depth of the bore (also known as the width or height of the seal).

Note:

When the width of the seal is not strictly specified, the depth of the

bore is usually made big enough so a seal might be replaced by a wider

one.

Sealing Lip material

Any special materials or considerations, such as stainless steel for the case and/or spring

Any special treatment or finish such as painted, polished edge, etc.

Oil Seal Designs From Global O-Ring and Seal

Global O-Ring and Seal offers a full line of oil seal designs in all industry standard sizes.

If you are a distributor or purchaser who may have need for our oil seal products, contact us

today to speak with one of our technical sales associates, request a no-obligation quote, or

place an order online from our extensive inventory.

Advantage

● The structure is simple and easy to manufacture.

● Lightweight and low consumables.

● The oil seal has a small axial dimension, is easy to machine, and makes the machine compact.

● The sealing machine has good performance and long service life.

● The oil seal has certain adaptability to the vibration of the machine and the eccentricity of the spindle.

● Easy to disassemble and easy to test.

Category: TYPE TC OIL SEAL

Related Category: TYPE TC OIL SEAL